Vetropack starts up new furnace in the Czech Republic

29.01.2024: The Vetropack Group, one of Europe's leading glass packaging manufacturers, has commissioned a new melting furnace as well as two servo-driven glass forming machines and another glass forming machine at its Czech site in Kyjov. The process of heating up the modernised melting furnace commenced on the 15th of January – the first glass is expected to be produced today. Originally, production was scheduled to start in the autumn of last year. However, owing to the tense market situation, Vetropack postponed commissioning by a few months.

The Czech site of Vetropack Moravia Glass, a.s., located in Kyjov, celebrated its 140th anniversary last year. It is one of the key glass packaging suppliers for Central Europe, symbolising the successful outcomes of integrating tradition with modern technologies. With the latest reconstruction work, the site reaffirms its commitment to innovation and sustainability in a dynamic market environment. "The path to increased sales lies in more modern and efficient production facilities," comments Boris Sluka, Managing Director of Vetropack's Business Unit Czech Republic and Slovakia. "While the market situation remains challenging, our proactive approach in seeking new customers has enabled us to, at least partially, supplement our production capacity."

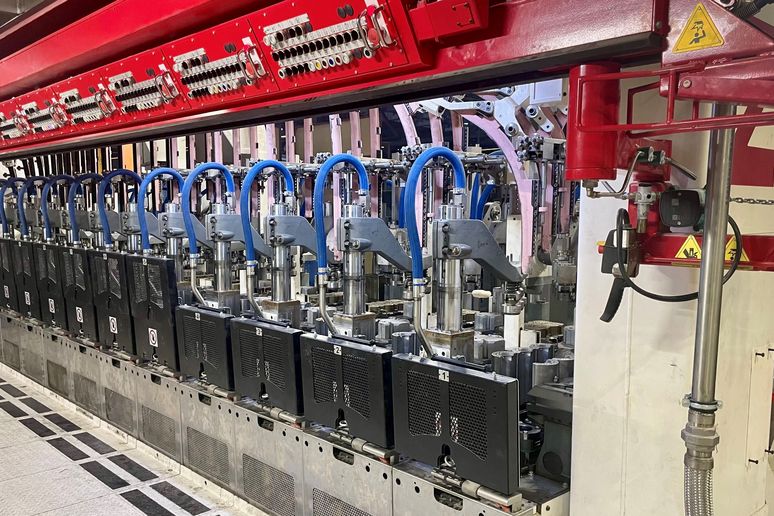

The retrofitted, state-of-the-art melting furnace is designed for producing coloured glass. It offers a higher capacity in comparison to the previous furnace. Additionally, two servo-driven NIS glass forming machines as well as an AIS glass machine have been successfully launched at the site.

The two NIS glass forming machines represent a significant milestone for Vetropack. "Servo technology offers numerous advantages, with the NIS machine standing out for its extremely accurate control of the glass-forming process. As one of the most flexible and high-performing machines available in today’s market, it substantially lowers energy consumption, improving efficiency and capacity," says Boris Sluka. "Moreover, the machine improves the working environment by minimising noise and enhancing operator safety through reduced human interaction when compared to pneumatic devices. We take pride in inaugurating these cutting-edge machines in Kyjov."

Vetropack had initially scheduled the commssioning of the state-of-the-art furnace and the two NIS machines for autumn of 2023. "Due to inflation and uncertainty in the European market, Vetropack opted to postpone the start of production to the beginning of 2024, as the company announced in October."

You will find a visualisation of the melting furnace here.

Downloads

- PI_E_Vetropack_Schmelzwanne_Kyjov.pdf (pdf)

About Vetropack

Vetropack Group is one of Europe's leading manufacturers of glass packaging for the food and beverage industry with around 4,000 employees and net revenues of CHF 899.4 million in 2022. Vetropack has state-of-the-art production facilities as well as sales and distribution offices in Switzerland, Austria, the Czech Republic, Croatia, Slovakia, Ukraine, Italy, the Republic of Moldova and Romania.

At Vetropack, we enable people to enjoy food and beverages as safely as possible by providing solutions that combine optimum elegance with maximum responsibility. We view glass as the most sustainable packaging solution – and the perfect material to ensure that food is packaged safely. Our holistic Service plus+ approach helps our customers to optimise their value chains and guarantee consumers' safety. Close, long-lasting relationships are the hallmarks of our collaboration with partners. Guided by our understanding of environmental responsibility and cost efficiency, we aim to minimise our carbon footprint throughout the supply chain, and we are committed to recycling as the key to optimising product life-cycles.